Paint Polishing | Ceramic Coating

Caseih Quadtrac 550

The restoration and ceramic coating of this CaseIH QuadTrac 500 represented a comprehensive refurbishment effort. The project initiated with an APC (All-Purpose Cleaner) scrub, serving as a modern equivalent to the traditional clay bar treatment for addressing oxidation on single-stage paint. Initial cutting was performed with rotary polishers, followed by orbital polishing to refine the paint further. Our objective was to maximize the paint's gloss before encapsulating it with our ceramic coating technique. All red components were brought to their optimal shine, including the roof, hood, platform/stairs, and rear fender/tank assembly.

What we accomplished

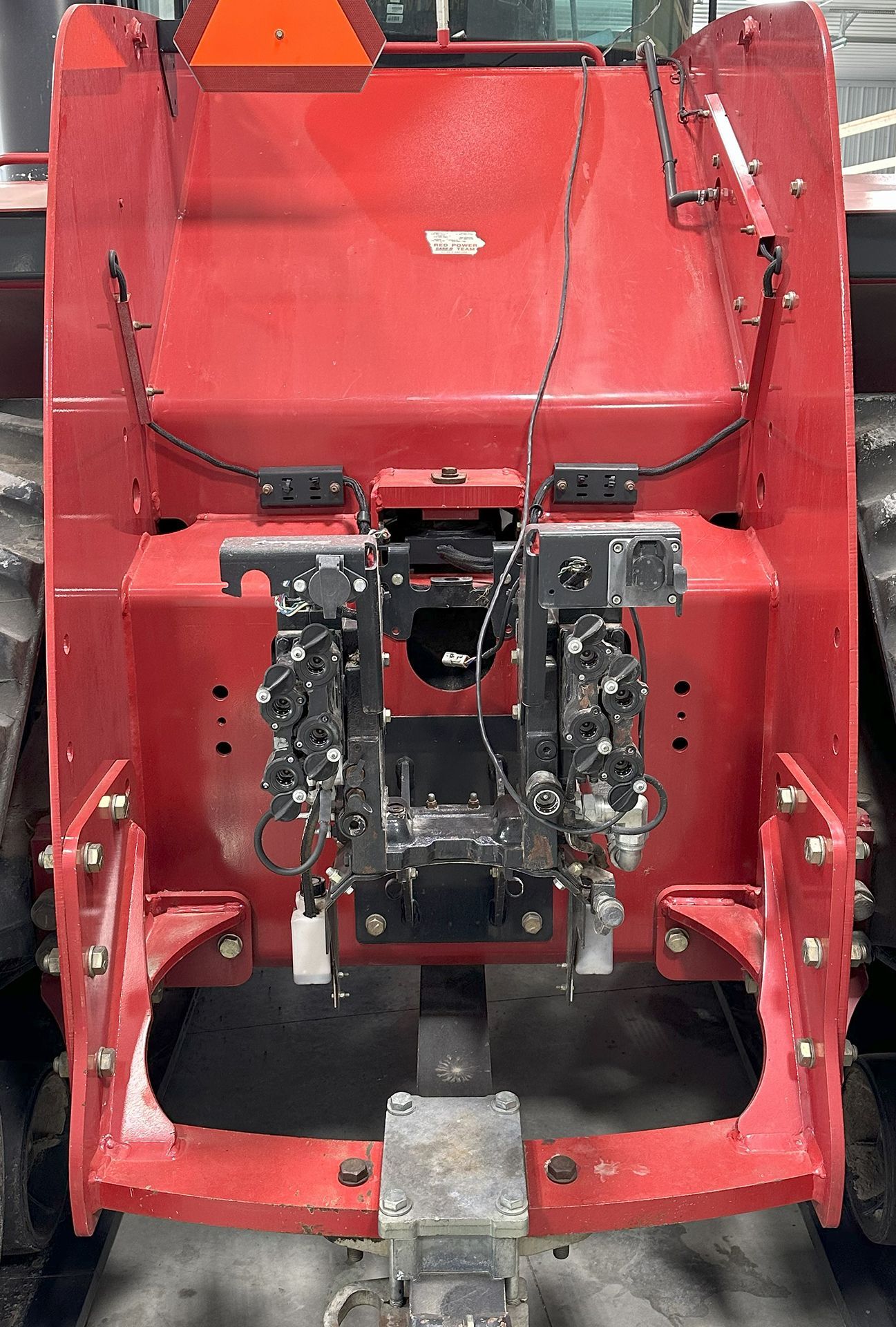

The black frame, major track components, toolbox, lights, and the under-roof apron underwent polishing to enhance their shine and clarity. Notably, the polishing extended beyond the visible areas to the lower edge of the frame, beyond the track line. After approximately 20 man-hours of polishing, every panel and exterior surface was meticulously prepared, and stripped of any residual oils and contaminants.

You know how reading a long list can send your gaze into the void, as if you're staring into the great unknown? Well, to save you from that hypnotic trance, let's talk about what we didn't slather in ceramic coating: the rubber tracks. Yep, those bad boys were left as nature intended—untouched and uncoated.

Now, for those of you who thrive on detail and can juggle lists like a circus performer, here’s a fun rundown. We either gave a spa day (polished/prepped/coated) or just a quick makeover (prepped/coated) to practically everything else: the roof (not just any roof, the roof), its stylish apron, the lights (because they need to shine bright like a diamond), glass (for that crystal-clear view), lower cab trim (can't forget the trim), air intake, exhaust (to breathe easy), stairs (watch your step), platforms (for that elevated feel), battery cover (gotta protect the power source), fenders (flaunting those curves), hood (the tractor’s crowning glory), frame (the backbone of this beauty), major track components (they’re major for a reason), toolbox (every tractor's trusty sidekick), rear tank (keeping it fueled), rear hydraulic connections (the unsung heroes), and the pièce de résistance, the complete articulation mechanism (because flexibility is key).

So, in a nutshell, if it could stand still long enough, we probably coated it. Except for the rubber tracks, of course—they’re just too cool for school.

Schedule your equipment upgrade.

Send us your request, and we'll get in touch to schedule a consultation call. Looking forward to chatting with you!